Rain and cold delayed potato harvest throughout Wisconsin in 2018. Many farms were still digging potatoes in late October and into November. Temperatures below freezing took a toll on numerous fields when potatoes suffered frost damage.

No one wants to see another harvest like 2018, but perhaps there is value in reviewing the causes and consequences of frost damage and discussing strategies for managing frost-damaged potatoes.

Frost damage occurs when tuber temperature drops below approximately 30 degrees Fahrenheit and tuber tissues freeze.

Frost damage occurs when tuber temperature drops below approximately 30 degrees Fahrenheit and tuber tissues freeze.

Potatoes that are closer to the surface are more likely to experience freezing temperatures than those deeper in the soil. Green potatoes, which are at the soil surface, will undoubtedly be the first to suffer from frost damage.

Low spots in a field collect cold air and are more susceptible to frost damage than higher elevations.

Soil moisture content also influences the susceptibility of potatoes to frost damage. Soils with lower water content cool more rapidly than soils with higher water content.

Multiple environmental factors, including strong winds, clear skies and low humidity, increase the likelihood of frost damage when temperatures drop to below freezing.

Frozen potato tissue is no longer viable and cannot be healed. Rapid water loss begins as soon as the affected tubers thaw. Frost-damaged tissues develop wet patches on the skin as moisture leaks from lenticels.

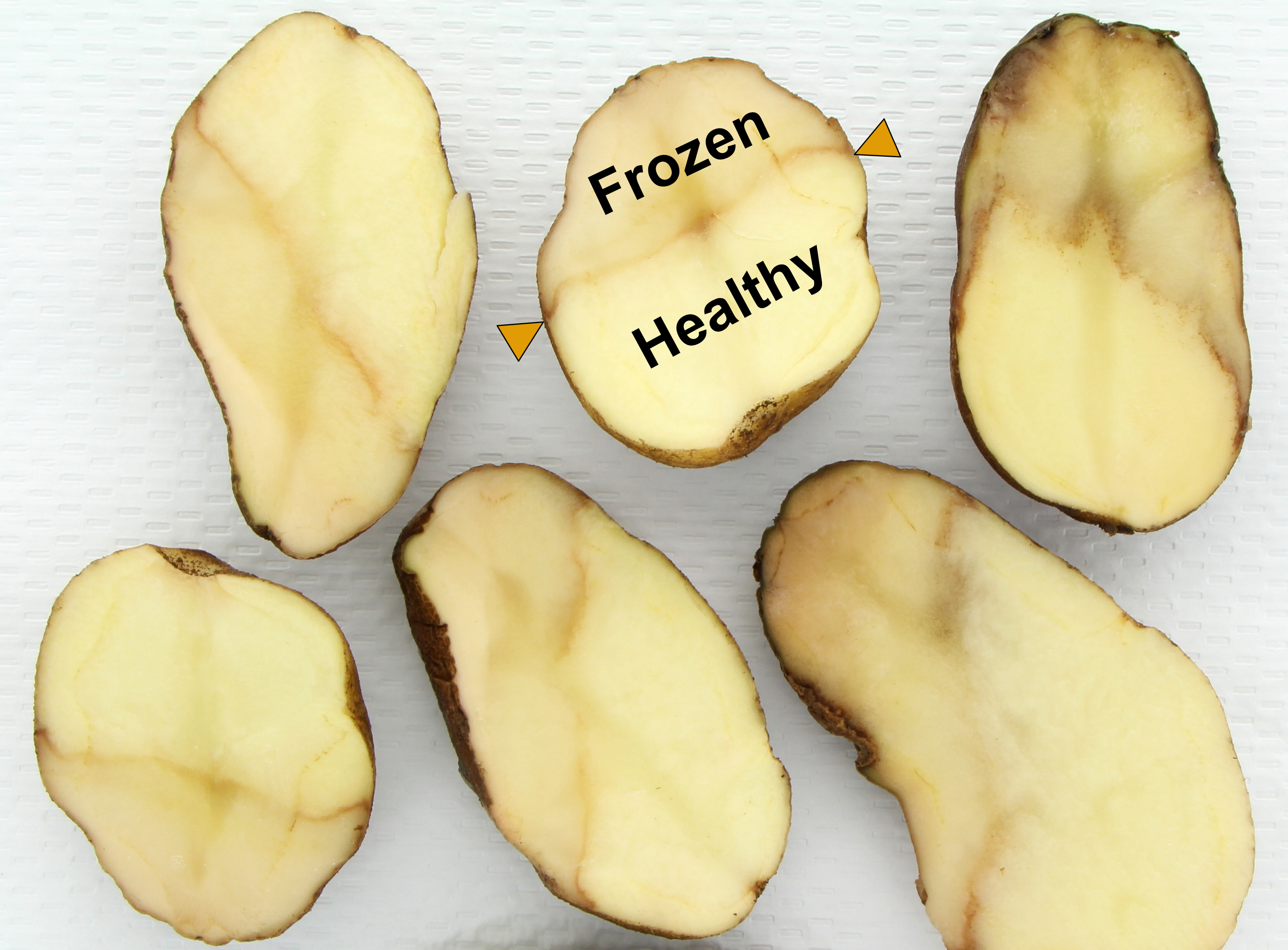

Underlying tuber flesh oxidizes with time and will appear gray after a few days. Frost-damaged tissue loses its structural integrity and feels soft to the touch as soon as it thaws. Within days of thawing, affected regions begin to shed soggy masses of formerly frozen tissue. Adjacent, non-frozen tissue remains viable, and a closing layer will form at the interface between healthy and frozen tissue if conditions allow. The threat of infection by pathogenic organisms is very high until wound periderm formation is complete.

Strategies for managing frost-damaged potatoes are based on conventional best practices for storing potatoes. To begin with, consider not harvesting fields where frost damage is extensive. In some cases, crop insurance may be the best option. Potatoes from fields with extensive frost damage—such as those with a high incidence of pink rot or soft rot—are unlikely to store well.

For chip and fry processing potatoes, explore options for running the material through a processing plant directly off the field. This option depends on whether the potatoes have undergone extensive cold-induced sweetening prior to harvest. Prolonged exposure to cold temperatures promotes accumulation of reducing sugars in tubers and dark color in finished products. Varieties differ in their resistance to cold-induced sugar accumulation, and those that are slow to accumulate sugars have the best chance of producing acceptable products after exposure to cold temperatures.

For fresh market potatoes, packing and shipping directly off the field is unlikely to be a good option. It is very difficult to grade out frost-damaged tubers, and damaged regions on tubers that aren’t pulled from the line are likely to become apparent to customers after shipping.

Once a decision has been made to store frost-damaged potatoes, the storage manager needs to establish priorities for stabilizing the stored material and delivering a saleable product. The highest priority should be maintaining the quality of potatoes that have not been frozen.

As potatoes are being loaded into storage, remove as many damaged tubers as possible. Make sure workers have a clear idea of what frost damage looks like. After bin loading, establish conditions that promote wound healing and maturation of the skin while at the same time suppressing the growth and spread of rot-promoting bacteria. The rate of wound healing and the potential for rot both increase rapidly as the storage temperature increases. A temperature of 50 degrees is a compromise that allows for wound healing to occur in about two weeks without strongly promoting the activity of soft rot bacteria. If pulp temperatures are lower than 50 degrees, warm the pile slowly and reduce the humidity in the supply air to well below 95 percent. The optimal relative humidity of the supply air depends strongly on the amount of water that needs to be removed from the pile. An empirical approach to determining an appropriate value is likely to work as well as a theoretical approach. Set the humidity of the supply air so that the return air has a relative humidity of about 90 percent. The goal is to prevent condensation of warm, moist air on cool potatoes as the air moves up through the pile. Condensation promotes disease and slows the removal of water from-damaged potatoes. An unavoidable consequence of this approach is that potatoes on the bottom of the pile will lose water faster than usual and are likely to have pressure flattening and bruising earlier than in a typical year.

As potatoes are being loaded into storage, remove as many damaged tubers as possible. Make sure workers have a clear idea of what frost damage looks like. After bin loading, establish conditions that promote wound healing and maturation of the skin while at the same time suppressing the growth and spread of rot-promoting bacteria. The rate of wound healing and the potential for rot both increase rapidly as the storage temperature increases. A temperature of 50 degrees is a compromise that allows for wound healing to occur in about two weeks without strongly promoting the activity of soft rot bacteria. If pulp temperatures are lower than 50 degrees, warm the pile slowly and reduce the humidity in the supply air to well below 95 percent. The optimal relative humidity of the supply air depends strongly on the amount of water that needs to be removed from the pile. An empirical approach to determining an appropriate value is likely to work as well as a theoretical approach. Set the humidity of the supply air so that the return air has a relative humidity of about 90 percent. The goal is to prevent condensation of warm, moist air on cool potatoes as the air moves up through the pile. Condensation promotes disease and slows the removal of water from-damaged potatoes. An unavoidable consequence of this approach is that potatoes on the bottom of the pile will lose water faster than usual and are likely to have pressure flattening and bruising earlier than in a typical year.

It may take a few weeks to dry up the damaged tubers. It is important to prevent soft rot from spreading rapidly during this time. Careful monitoring of bins is required to catch problems early. Rapid onset of extensive disease may signal a lost cause that should be shipped as soon as possible. Potatoes with moderate disease symptoms can be treated with products such as FruitGard Wipeout, FruitGard Maintenance and ZeoAir that have chlorine dioxide as the active ingredient. Products containing peroxyacetic acid/peracetic acid can also be effective in suppressing the spread of soft rot bacteria.

Frost-damaged potatoes are not expected to store well or long. Disease is likely to linger and may flare up periodically. It is a challenge to restore acceptable sugars in processing potatoes that have gone off-color. Extra vigilance is required when packing fresh-market potatoes because of concerns over debris and disease.

Paul Bethke is a plant physiologist with the USDA’s Agricultural Research Service and the University of Wisconsin-Madison. Troy Fishler is the research manager of the potato and vegetable facility at UW’s Hancock Research Station.

A version of this article previously appeared in the December 2018 issue of Badger Common’Tater. It is published in Potato Grower with permission from the Wisconsin Potato & Vegetable Growers Association.